The strength increasing anorganic fillers used in the industry is one of the most important inputs of modern composite materials. In addition to various basic fiber materials, our company offers centrifuged microfiber materials for different industrial applications. Basic fibers are produced uninterrupted continuous fiber bundles to the required fiber length. The fiber bundle is made from diluted material. Each of these bundles is formed by the combination of tens of filaments and is cut to the desired length following the cooling process.

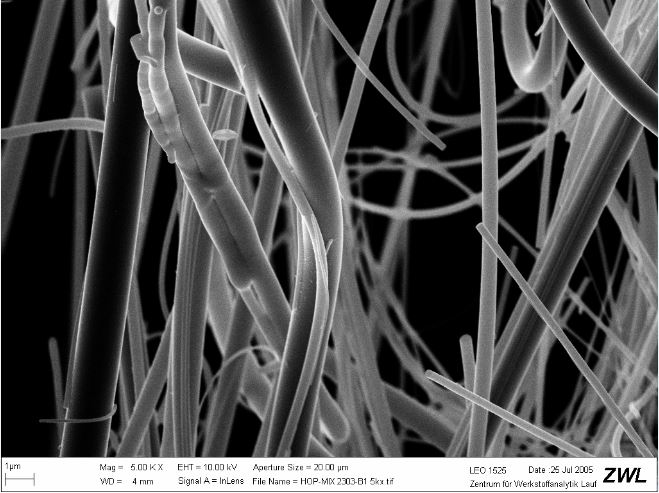

The centrifuged microfibres are sprayed from the extruder head, resulting in a much smoother distribution than conventional fibers. So its appearance is more like a stack than a fiber.

HOP-MIX is one of the centrifuged glass microfibers. These fibers are obtained after very sophisticated processes. The glass is first liquefied, then sprayed into very fine fibers. These fibers are then found in casting and can be bedded in a mold. The chemistry of the glass and the small diameter of the fibers enable a transparent end product, even in the most intensive applications. Systematic distribution of very fine fibers creates a high resistance over the whole structure. HOP-MIX can be used simultaneously on a large surface, replacing pyrogenic silicas as a cost-cutting substitute.